Synopsis: Right here’s a have a look at some simply made instruments that may make life simpler within the store: the dovetail marker, the glue-bottle wrench, a drawer opening strap, pins for centering a tabletop, spacers for aligning drawer components when slicing dovetails, and a foolproof depth cease for drilling.

Some instruments in your store can’t be purchased. Or don’t have to be. Many are particular to your wants and operations. Sure ones may be used solely often, however are helpful to have when wanted, simply to make life a bit simpler. They are often made with a minimal of fuss and tools, usually with simply scraps put to good use.

Dovetail marker

You should buy a steel dovetail marker, however in half an hour or much less you can also make your individual. Furthermore, you can also make a fleet of them at totally different angles if you want.

Fast to make. Beginning with an over-length piece of inventory, set up the shoulders on the desk noticed. Then reduce the cheeks on the bandsaw. Whereas the inventory continues to be lengthy, pencil in your angle traces, after which reduce them freehand on the bandsaw. A handsaw would deal with these duties as properly. Lastly, crosscut the marker and refine the angles with a hand airplane or sanding block.

|

|

Glue-bottle wrench

Glue-bottle wrench

Who hasn’t cursed their glue bottle when all of the dried glue makes it arduous to open the nozzle? A shopmade wrench stored close to the bottle takes minutes to create and makes for simple opening each time. I’ve made a couple of picket wrenches, 3⁄8 in. by 1 in. by 4 in., out of scrap wooden. Drill a 9⁄16-in. gap close to one finish, then make two parallel cuts with a noticed and it’s accomplished.

Drawer opener

When becoming flush doorways or drawers, it’s troublesome to get them out of their openings earlier than the pulls are connected. To unravel the issue, I’ve a 1-in. by 5-in. piece of 25-gauge hose clamp strap with the final inch bent again and hammered, then opened barely. I pressure it between the drawer and the divider till the bent piece springs again, then pull the drawer out. Alternatively, an L-shaped Allen wrench can be utilized for a similar objective; simply choose one smaller than the drawer’s hole.

Centering pins

To maintain your tabletop in place whenever you’re attaching its base, these quick-to-make centering sticks are invaluable. They’re 1⁄4-in. or 3⁄16-in.-dia. brass welding rods, reduce to about 6 in. and sharpened. With the highest and base the other way up, I align the middle of the bottom with the centerline of the desk, and hammer within the one centering rod at every finish of the bottom to maintain it from shifting whereas I mark the remainder of the screw holes utilizing an axe. A 20d or 30d nail would additionally work.

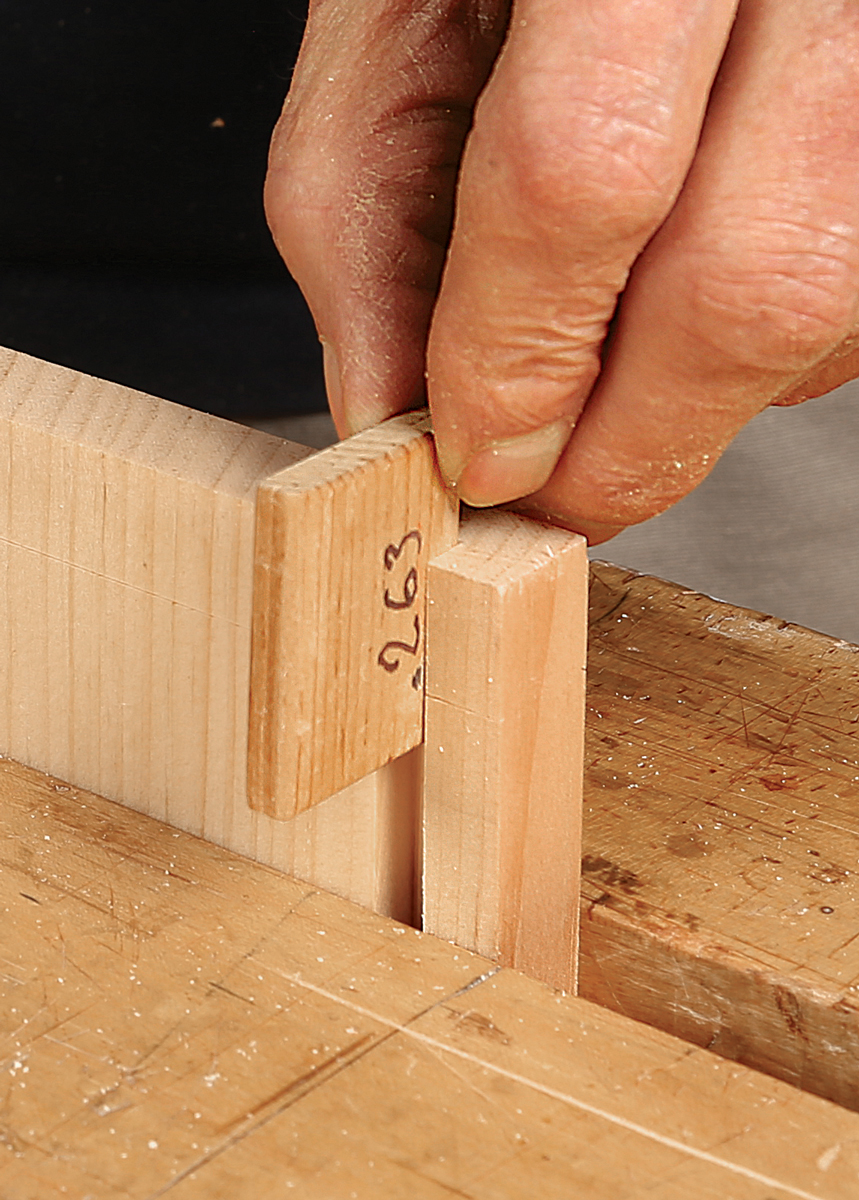

Alignment spacers

Whether or not you’re slicing pins or tails first, whenever you switch one to the opposite it’s important that the grooves for the drawer backside line up completely so they’ll run uninterrupted all the way in which across the drawer field. Easy picket spacers are a simple approach to resolve the dilemma.

Constant depth cease

You by no means wish to by chance drill your shelf holes by the cupboard facet. A easy, drilled cylinder that slides over the drill bit and stops the reduce on the proper depth is a no-mistake gadget for the duty.

Drill and trim to size. Clamp your dowel tightly in a hand screw, and drill a gap the identical measurement or barely bigger than the diameter of the supposed drill bit. The outlet you drill doesn’t should go during the dowel. Then reduce the dowel to size based mostly on the specified depth of gap. You possibly can fine-tune the depth of the holes you’ll be drilling by trimming the cease or including washers.

From High-quality Woodworking #308

From High-quality Woodworking #308

To view the article, please click on the View PDF button under.

Join eletters right now and get the newest strategies and how-to from High-quality Woodworking, plus particular presents.

Obtain FREE PDF

whenever you enter your e-mail tackle under.