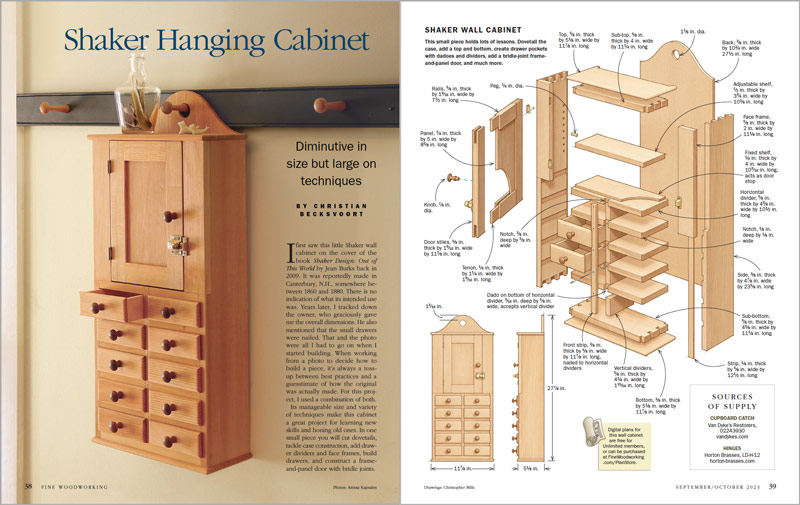

Synopsis: This small Shaker cupboard packs quite a lot of totally different methods right into a small challenge. Whereas constructing it, you’ll minimize dovetails, deal with case development, add drawer dividers and face frames, construct drawers, and assemble a frame-and-panel door with bridle joints. Not solely that, however if you find yourself achieved, you’ll have a fine-looking Shaker replica to get pleasure from.

I first noticed this little Shaker wall cupboard on the quilt of the e book Shaker Design: Out of This World by Jean Burks again in 2009. It was reportedly made in Canterbury, N.H., someplace between 1860 and 1880. There isn’t any indication of what its supposed use was. Years later, I tracked down the proprietor, who graciously gave me the general dimensions. He additionally talked about that the small drawers have been nailed. That and the picture have been all I needed to go on after I began constructing. When working from a photograph to determine construct a chunk, it’s all the time a toss-up between finest practices and a guesstimate of how the unique was truly made. For this challenge, I used a mix of each.

Its manageable measurement and number of methods make this cupboard an excellent challenge for studying new expertise and honing outdated ones. In a single small piece you’ll minimize dovetails, deal with case development, add drawer dividers and face frames, construct drawers, and assemble a frame-and-panel door with bridle joints. Lastly, I glued the carcase collectively and glued skinny face-frame strips on the decrease half of the perimeters to cowl the dadoes.

5 horizontal and 5 vertical dividers

After sanding and assembling the case, I milled the 5 horizontal dividers (taking closing dimensions immediately from the case), dadoed them for the vertical dividers, and notched them for the entrance strip. On all 5, each entrance corners have been notched for the face-frame strip. I slid the horizontal dividers into place and put in the entrance strip over them.

Subsequent, I measured for the 5 brief vertical dividers. Then I minimize and put in them from the again. For each the horizontal and vertical dividers I used a friction match. Be happy to make use of glue if the components are a bit free. I drilled and pinned the horizontal divider to the verticals. Then I glued on the 2 wider, higher face frames, and planed and sanded the whole entrance.

Add the highest and backside

The precise high and backside each get a roundover profile on the entrance and sides. I formed the profile by hand with a block airplane and sandpaper. You additionally might minimize the profile on the router desk with a roundover bit. Glue the highest and backside onto the sub-top and sub-bottom. The best way the cupboard is constructed, the sub-top acts as a door cease. For the underside door cease, I glue a set “shelf” to the highest of the highest horizontal divider.

Bridle joint your strategy to a frame-and-panel door

The small door on the high of the cupboard is frame-and-panel. I made a decision on full bridle joints in all 4 corners and minimize them on the desk noticed. As soon as the door was glued, fitted, sanded, and hinged (Horton Brasses, LD-H-12), I added the small cabinet catch (Van Dyke’s Restorers, 02243930). I needed to take away the clear coat end on the catch, and, as I did with the hinges, darken it with Antiquing Resolution (Constantine’s Wooden Middle).

Christian Becksvoort is a longtime contributing editor and skilled in Shaker furnishings.

Images: Anissa Kapsales

Drawings: Christopher Mills

From Fantastic Woodworking #305

To view the whole article, please click on the View PDF button under.

Extra from Christian Becksvoort

Join eletters in the present day and get the most recent methods and how-to from Fantastic Woodworking, plus particular gives.

Obtain FREE PDF

whenever you enter your e mail tackle under.