[ad_1]

Tansu drawers are constructed otherwise from their western counterparts. They’ve pinned joinery on the corners, and the underside of a tansu drawer, as a substitute of being slotted into grooves, is pinned on to the underside of the drawer field. In use, the entire backside is supported by the mud shelf beneath it. This sort of cross-grain attachment could be problematic in wider drawers, so for the three large drawers, I made bottoms composed of two or extra items tongue-and-grooved collectively to allow them to broaden and contract. I additionally used excessive ring depend, very dry, vertical-grain western purple cedar.

Step one is to confirm the match of every drawer entrance, and decide the orientation. As a result of I generally is a little bit of a grain nerd, I attempt to hold all the pieces oriented in the identical path because it got here from the board; that manner when gentle hits it, no piece will replicate otherwise from the others. Tansu drawer fronts ought to be cosy, however not tremendous tight. (Professional tip: Don’t push all of them the best way flush, as they is perhaps extraordinarily tough to get again out. Belief me on this.)

Tansu drawers begin with rabbets

As soon as all the fronts are oriented and marked, it’s again to the desk noticed for rabbeting. I rabbet each ends and the underside edge of every drawer entrance, after which, utilizing a chamfer aircraft, I lower a forty five° chamfer alongside the within high fringe of the drawer entrance.

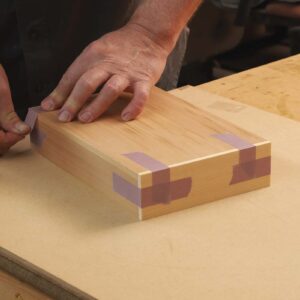

Tape the drawer field and pin it

With all of the drawer elements made, it’s time to drill for pins. Utilizing tape, I assemble every drawer dry, then do all the pin format, and drill. For drawer joints, I usually use two pins close to the highest. This not solely strengthens the weakest a part of the drawer, however I additionally assume it appears to be like cool. The pins I exploit are literally 3⁄32-in.-diameter toothpicks. I lower them in half, so every toothpick yields two pins.

When all the holes are drilled, it’s time to start out gluing. Leaving the tape connected to the underside, I take away the underside and set it apart (noting its orientation). Subsequent, I launch the tape on one joint and open the drawer pretty flat. After making use of glue to the joints, I pull the tape tight and drive in pins dragged by means of glue. When one facet is pinned, I lower off the pins, then repeat on the opposite facet. Subsequent I run a bead of glue across the perimeter of the body, re-tape the underside, and drive its pins. As a result of this course of takes a bit time, I like to recommend utilizing a glue with an prolonged open time. Apply clamps and put aside. When all the glue has cured, pull the tape and aircraft the drawers to suit.

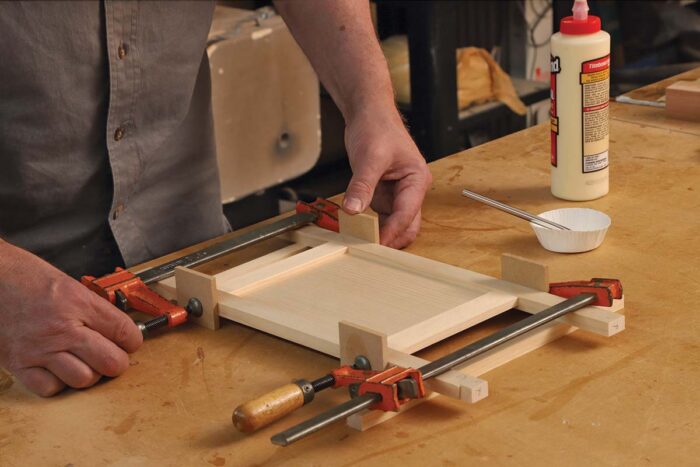

Suggestions for sliding tansu doorways

With the drawers full, I transfer on to the mortise-and-tenon, frame-and-panel doorways. To make the mortising of those small elements safer and the glue-up simpler, I depart the stiles an inch or extra over size on each ends till after meeting. As a result of these are gentle doorways, be conservative with the quantity of glue you employ. A really gentle wetting on the tenon and a light-weight coat within the mortise is loads. If squeeze-out could be averted, it ought to be. I insert two rails into one stile, slide within the panel dry, then rigorously faucet on the opposite stile, ensuring the panel edge doesn’t bind. Then I clamp, measure for sq., and let treatment. When the glue has dried, I noticed away the additional materials on the stiles and lower rabbets on the high and backside of every stile to match the rabbets on the rails.

Final, utilizing a rabbet aircraft, I regulate the match of the doorways till they slide freely (a bit wax within the grooves helps so much).

-That is the second of three posts for this undertaking. Half 3: Shopmade tansu {hardware} on Feb twenty eighth. In fact, when you can’t wait, the article PDF is on the market under, and the digital situation is on the market to Limitless members now!

Join eletters as we speak and get the most recent methods and how-to from Wonderful Woodworking, plus particular affords.

[ad_2]