[ad_1]

Dentil, or teeth-shaped, moldings have a protracted historical past. The Greeks positioned dentils into the capital part on the high of their columns. Furnishings makers have used them extensively to render a extra classical taste to a given piece. Thomas Chippendale included the Greek key and block dentil into lots of his designs.

In America, Thomas Elfe, a mid-18th century cabinetmaker from Charleston, S.C., was accustomed to Chippendale’s work and used dentils fairly successfully in his personal items. Exterior of Philadelphia, the Pennsylvania Germans developed dentil motifs that mirrored a extra rural taste acceptable for his or her bulkier, much less refined furnishings.

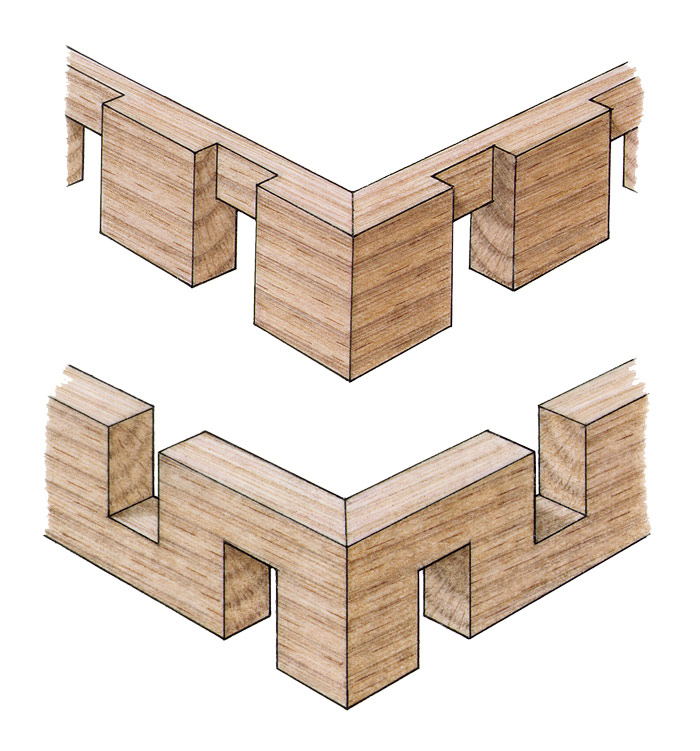

In copy work, you should be cautious to place the dentil in the best place. That’s not as foolish a warning as you would possibly suppose. A number of manufacturing unit “interval” furnishings will get this element incorrect, putting the dentil as the primary aspect of a cornice. In contrast, most American furnishings from the English custom has the dentil situated above the frieze or within the higher part of the crown. Right here I’ll cowl two frequent kinds of dentils: block and Greek key.

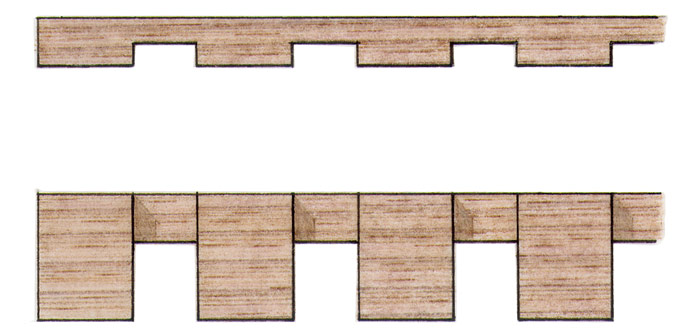

Block dentils are the commonest

For a refined look, block dentil moldings ought to start and finish on a full tooth, though yow will discover items the place this rule hasn’t been adopted. Just a few primary calculations, mixed with a bit fudging throughout milling, make ending the dentil on a full tooth straightforward to perform. The method could seem a bit difficult the primary time you do it, however it’s actually fairly easy. Take the size of the molding, work out the scale of every unit ( a void and a tooth), and divide the size by the unit measurement to get the divisions. The one wrinkles are including the overhang and ensuring that you find yourself on a full tooth. The identical course of is used for the entrance as the edges.

The dentil ought to finish on a full tooth, and every unit is a tooth plus a void. So to do the structure, subtract the final tooth from the general size of the molding to determine the variety of full items that may match throughout the case. Clearly, you’ll not often find yourself with an entire quantity, however don’t fear about that.

Now it’s time to see whether or not the dividers are set correctly. Utilizing a bit of scrap, mark out 24 divisions with the dividers. Tweak them till you come out proper on the cash, or inside a hair.

Subsequent, utilizing a bit of milled inventory a number of inches longer than the dentil wanted, draw a centerline down the piece (if making two rows at a time). Then, starting a number of inches from one finish, mark out the variety of divisions. (The additional inventory on every finish permits you to lower the primary and final tooth to suit the piece. Right here’s the place you fudge a bit if the structure isn’t actual.)

You might proceed from right here proper to the desk noticed, however to keep away from confusion, it doesn’t harm to make one other set of marks that clearly outline every void and tooth. To do this, set the dividers to the width of the void, and stroll off one other 24 divisions, which signify the voids. Utilizing a sq., lengthen all the marks, edge to edge. Final, mark the areas to be lower. Earlier than going to the noticed, maintain up the marked-off inventory towards the case to double-check your structure.

Machine the voids utilizing a dado blade

To soundly management the motion of the skinny inventory throughout the noticed and keep away from blowout, I make a carriage utilizing two items of three/4-in. thick medium-density fiberboard (MDF) screwed collectively at proper angles and connected to a pair of miter gauges.

With the carriage in place, increase a 1/4-in. dado set till it cuts a 5/16-in.-high notch. Use the kerf within the carriage to register the structure marks. Subsequent lower all the 5/16-in. deep notches alongside one fringe of the strip. Then reset the dado peak for rather less than a 1/4-in.-deep lower. Lay the strip on its face and lower the shallow grooves.

Return the dado to the 5/16-in. setting and lower the voids alongside the opposite facet (if making two units directly). To tear the inventory into two units, use a zero-clearance insert plate and a protracted push stick. Despite the fact that the strips are stronger than they give the impression of being, deal with them gingerly.

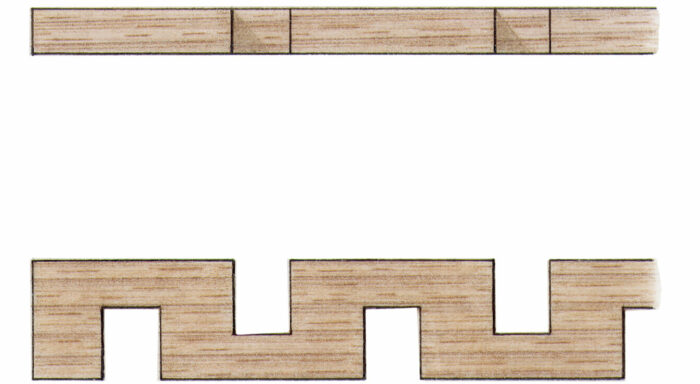

The Greek key

The cornice with the Greek key proven on the clock was taken from a bit made by Thomas Elfe In 1765. For the needs of symmetry, the molding ought to finish In vertical members on the corners, and the adjoining voids ought to both be on the high or backside.

In contrast to on the block dentil, cuts should be made on either side of the inventory, so you’ll be able to’t mill two units directly. However just like the block dentil, the molding is lower on the desk noticed utilizing the identical sort of carriage. As with the block dentil, work out a unit, then make the mandatory calculations to do the structure.

Mount the dentil to the crown

One of the best ways to make sure that the dentil matches your piece precisely is to put the strip atop the frieze, mark the size after which lower it. I take advantage of a miter noticed to chop the dentil to size in addition to to miter the corners. When doing this, it’s necessary to assist the molding on all sides. In any other case, you might discover little tooth flying everywhere in the store. I make a holder that attaches to the miter noticed fence. It’s nothing greater than a straight block of wooden with a rabbet lower into it. The rabbet acts as a fence to assist tl1e molding. Earlier than slicing the dentil, make two cuts into the block, one at 90° and one other at 45 0. The clear kerfs will forestall blowout and act as registration marks when slicing the dentils.

As soon as lower to suit, apply a dab of glue to the tooth after which clamp the molding in place with masking tape.

—Initially printed in 2013. Textual content is excerpted from Steve’s article “Two kinds of dentil moldings” in Superb Woodworking #154—Feb/Mar 2002

Join eletters in the present day and get the newest strategies and how-to from Superb Woodworking, plus particular gives.

[ad_2]