[ad_1]

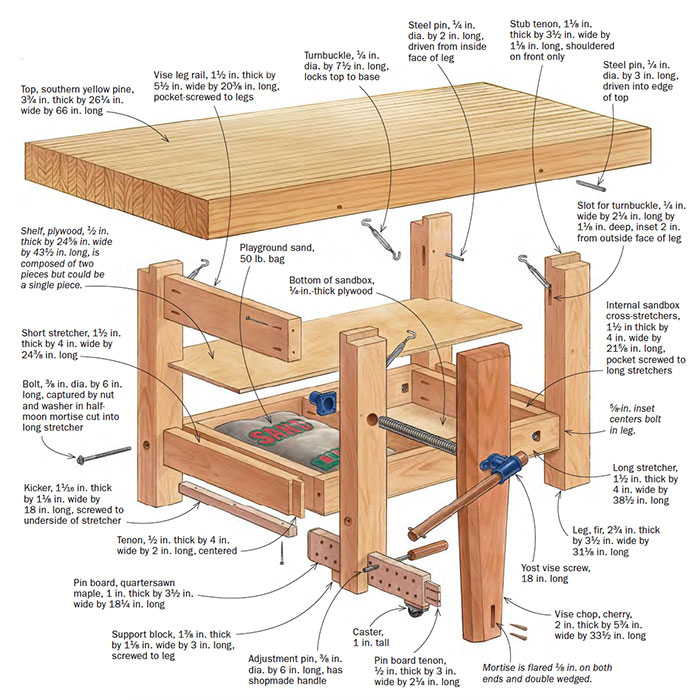

Synopsis: Perfect for many who are watching their budgets, this workbench has a basic design that may serve your woodshop for years. It’s made utilizing extensively obtainable {hardware}, building lumber, and a few sandbags. The legs and high are joined with stub tenons and turnbuckles that lock onto metal pins. This building makes for a really steady bench that may be simply disassembled for shifting. However you’ll need to make this bench even when you don’t ever plan to maneuver it.

Once I constructed my first workbench, my workshop was within the basement of a home that I used to be renting. I knew that I’d be shifting earlier than too lengthy, and I would want to have the ability to choose up and carry my workbench out of the basement. However I additionally wanted a bench strong sufficient to not soar and dance everywhere in the workshop once I was planing a board or carving a chair seat. Utilizing extensively obtainable {hardware}, building lumber, and a few sandbags, I constructed a bench that was cheap and simple to maneuver, but nonetheless had the strong feeling of a basic workbench. I cherished that bench, and I’ve since constructed this one to a really comparable design.

Ranging from the highest

The benchtop is laminated from dimensional building lumber. Every time I am going to lumberyards I scan the stacks and purchase any boards with straight grain and few knots. I retailer them up within the tie beams in my workshop and pull them down as wanted to construct issues like jigs, bending kinds, shaving horses … or a workbench. I constructed the highest for this one whereas I used to be dwelling in North Carolina, the place southern yellow pine, a fantastically exhausting and heavy wooden, is standard-issue building lumber.

The benchtop is laminated from dimensional building lumber. Every time I am going to lumberyards I scan the stacks and purchase any boards with straight grain and few knots. I retailer them up within the tie beams in my workshop and pull them down as wanted to construct issues like jigs, bending kinds, shaving horses … or a workbench. I constructed the highest for this one whereas I used to be dwelling in North Carolina, the place southern yellow pine, a fantastically exhausting and heavy wooden, is standard-issue building lumber.

I chosen a batch of 2x10s, ripped them in half, and glued them as much as make a high 66 in. lengthy, 26-1 ⁄ 4 in. broad, and 3-3 ⁄ 4 in. thick. It’s excellent, however you don’t need to make one which thick or use yellow pine. I’ve made workbenches with spruce tops as skinny as 2 in. and so they additionally labored nice.

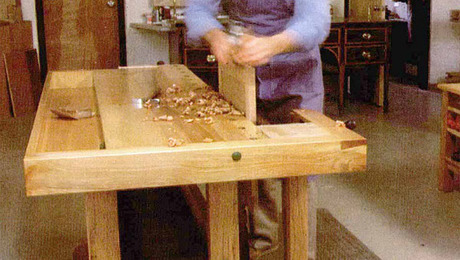

A very powerful function of this workbench is the way in which the legs and the highest are joined. The legs have stub tenons that go into matching mortises within the underside of the benchtop, and turnbuckles tighten the joints. I put in metal pins within the high and the leg close to the joints to obtain the hooks of the turnbuckle. When the turnbuckle is tightened, it pulls the benchtop and the legs collectively and seats the stub tenon in opposition to the mortise wall. This makes for a really inflexible joint. However when it’s time to maneuver, just some activates every turnbuckle fully frees the highest from the bottom.

Base notes

On my first workbench, the stretchers and legs had been solely joined by bolts. That made for a really steady bench, however I’ve since realized that it’s extra handy for transportation to completely be part of the 2 finish stretchers to the legs with glued mortise-and-tenon joints. Now I solely use bolts to hitch the entrance and rear stretchers to the legs. This implies I’ve fewer components bouncing round once I disassemble the bench for transport. And having fewer bolts to loosen speeds disassembly.

The entrance and rear stretchers have one bolt at every finish. The bolt passes by way of the leg and emerges right into a pocket lower within the stretcher the place a nut could be threaded on and tightened. The pockets are made by drilling a 1-in.-dia. gap and squaring one facet of it with a chisel so {that a} washer and nut can sit flat in opposition to that floor, pulling the leg and the stretcher collectively because the bolt is tightened. You’ll be able to match the closed finish of a wrench into the opening to carry the nut, or wedge a big flat-head screwdriver between the wall of the pocket and one of many faces of the nut to maintain it from spinning.

The shelf beneath my bench can also be the quilt of a field filled with sand. 100 kilos of playground sand retains the The shelf beneath my bench can also be the quilt of a field filled with sand. 100 kilos of playground sand retains the bench firmly in place, simply compensating for the sunshine weight of the softwood lumber that I used to construct the bottom. And the baggage are simply eliminated when the bench must be disassembled. The entrance and rear stretchers are linked by three pocket-screwed cross stretchers and skinned with plywood high and backside.

—Tim Manney builds chairs and makes reamers in South Portland, Maine.

Pictures: Jonathan Binzen.

Drawings: Derek Lavoie.

For extra photographs and illustrations, click on on the “View PDF” button beneath:

From High-quality Woodworking #307

Join eletters immediately and get the most recent methods and how-to from High-quality Woodworking, plus particular gives.

Obtain FREE PDF

while you enter your e mail tackle beneath.

[ad_2]