January 3, 2024 at 6:00 p.m.

By TUBOS.

Traditionally, vent pipes had been flashed with lead boots or with a no-hub connector, however at the moment there’s a quicker and simpler means!

Plumbing vent pipes are an integral a part of a constructing’s plumbing system and, extra particularly, its drainage system. Vent stacks are designed to work together with a constructing’s drain pipes, by permitting air into the plumbing system, which permits greywater and waste to move freely out of the constructing and permits sewer gasses and odors to correctly escape out of the constructing.

Plumbing vent pipes are an integral a part of a constructing’s plumbing system and, extra particularly, its drainage system. Vent stacks are designed to work together with a constructing’s drain pipes, by permitting air into the plumbing system, which permits greywater and waste to move freely out of the constructing and permits sewer gasses and odors to correctly escape out of the constructing.

As well as, plumbing vent stacks are required by code to be a sure top over the floor of the roof, usually 6-inches, however many contractors choose 8-inch heights. When insulation is added on a re-roofing mission to satisfy R-value necessities the vent stack top is successfully decreased by the thickness of the added insulation, and the vent stack top falls out of code compliance.

The Worldwide Plumbing Code (IPC): This requires plumbing vent pipes to increase vertically at the very least 6-inches (152 mm) above a roof, per Part 905.5, “Vent Connections and Grades.” Moreover, vent pipes have to be at the very least 12-inches (305 mm) away from a vertical floor. In places recognized for snow, the vent pipe must be at the very least 2-inches (51 mm) in diameter and 12-inches (305 mm) inside an insulated space of a constructing earlier than extending by means of the roof. Vents in these places additionally ought to prolong 24-inches (610 mm) above the roof.

The Worldwide Plumbing Code (IPC): This requires plumbing vent pipes to increase vertically at the very least 6-inches (152 mm) above a roof, per Part 905.5, “Vent Connections and Grades.” Moreover, vent pipes have to be at the very least 12-inches (305 mm) away from a vertical floor. In places recognized for snow, the vent pipe must be at the very least 2-inches (51 mm) in diameter and 12-inches (305 mm) inside an insulated space of a constructing earlier than extending by means of the roof. Vents in these places additionally ought to prolong 24-inches (610 mm) above the roof. 2010 Florida Constructing Code, Plumbing 904.1 Roof extension: All open vent pipes that reach by means of a roof shall be terminated at the very least 6 inches (152 mm) above the roof and never lower than 2-inches (51 mm) above the invert of the emergency overflow, besides that the place a roof is for use for any goal apart from climate safety, the vent extensions shall be run at the very least 7- toes (2.1 m) above the roof.

2010 Florida Constructing Code, Plumbing 904.1 Roof extension: All open vent pipes that reach by means of a roof shall be terminated at the very least 6 inches (152 mm) above the roof and never lower than 2-inches (51 mm) above the invert of the emergency overflow, besides that the place a roof is for use for any goal apart from climate safety, the vent extensions shall be run at the very least 7- toes (2.1 m) above the roof.

Traditionally, on industrial roofs, vent pipes had been flashed with lead boots under, or with a no-hub connector. Nonetheless, at the moment there’s a quicker and simpler means for industrial roofers to increase a vent stack that meets code and performs with out permitting any moisture into the roaofing meeting.

Pre-engineered and patented

Pre-engineered and patented

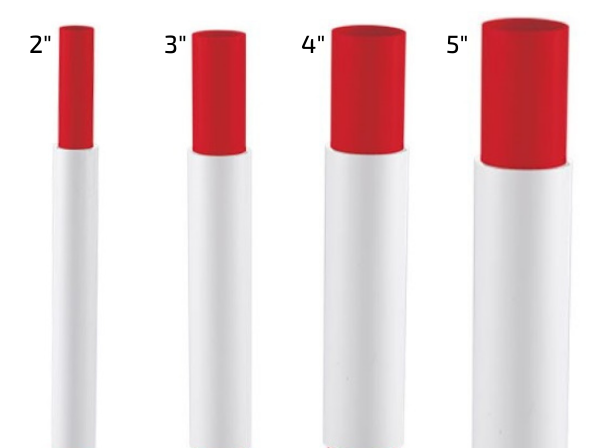

Tubos pipe extensions can be found in 2-, 3-, 4- and 5-inch diameters to accommodate most typical vent stack sizes, and are totally appropriate with each forged iron and PVC vent stacks. Every Tubos unit has a six-inch inner splice sleeve that matches down the within of the present vent stack, that forestalls water and moisture from leaking into the roofing meeting. The outer sleeve of the Tubos unit sits on prime of the present vent stack and could be flashed with a wide range of supplies and strategies together with thermoplastic or thermoset boots, a hose clamp and caulk.

As soon as put in, any water that seeps throughout the highest of the unique vent stack will move harmlessly into the vent stack or plumbing system and never into the industrial roofing meeting. “Sometimes we get questions concerning the potential air-flow discount,” mentioned Kevin Morris, CEO of Tubos. “However truthfully, a Tubos unit doesn’t influence the air move as a lot as a lead boot flashing does, and people have been used for many years. Moreover, the discount within the vent stack with a Tubos unit isn’t solely very minor, however the insert sleeve is simply 6-inches lengthy, which within the whole plumbing system is miniscule. We’ve by no means had a name again or guarantee situation because of a scarcity of air within the system, and actually, we’ve by no means had a guaranty situation for moisture within the roofing meeting both.”

Some contractors suppose no-hub connectors are quicker and cheaper. Nonetheless, there are a number of potential points with no-hub connectors. “For one, the diameter of the PVC pipe accessible is commonly not an actual match for the present vent stack,” mentioned Morris, “and they don’t seem to be assured to be watertight. In reality, if the applicator doesn’t use a tourque wrench to tighten the clamp to the right setting, they’re much extra more likely to leak.” As well as, no-hubs take longer to put in, normally require a bigger boot for flashing, and are usually not accessible by means of roofing distributors, that means that the contractor has to ship somebody to the ironmongery shop to get the supplies, which provides time and labor.

Against this, Tubos models are designed to assist roofing contractors do extra with much less. They’re quick and easy to put in, usually take lower than three minutes to put in, and could be a actual productiveness enhancer on the roof, notably if there are a number of vent stacks to deal with. Tubos models are put in in 4 straightforward steps. Simply measure, minimize, seal, and flash and also you’re achieved. Plus, every 28-inch-long unit could be minimize and used to increase two pipes, and extensions could be as much as 16-inches lengthy. They are perfect for use the place a tapered system is added, or a brand new light-weight insulating concrete deck is being poured.