[ad_1]

—This text is from FWW #21–Mar/April 1980.

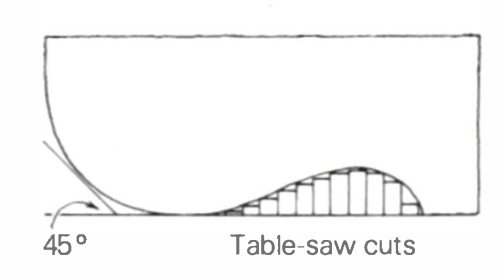

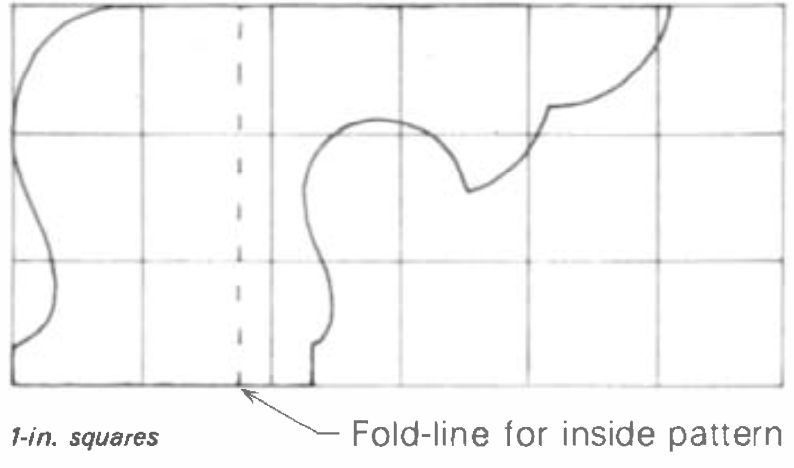

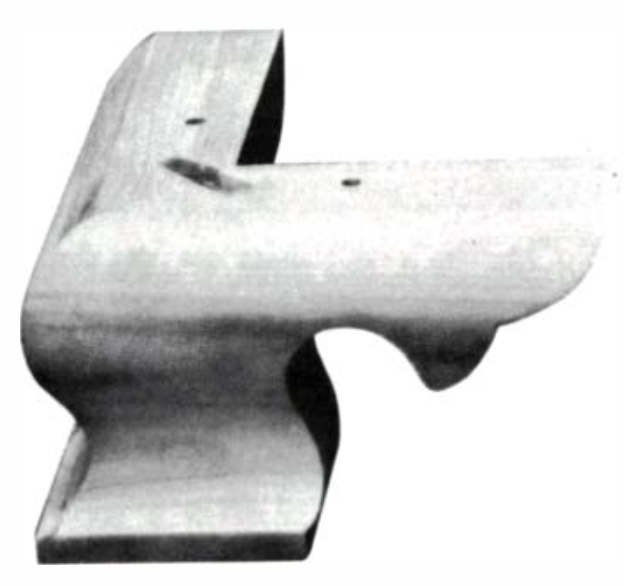

Ogee bracket toes, extensively used through the Chippendale interval of the early to center 18th century, type a good looking base for chests, tall clocks, desks, and lots of different items. Nonetheless, to many starting woodworkers, they seem troublesome to assemble. The standard manner includes shaping a protracted board of the required thickness, utilizing molding planes. The directions I’ve discovered for making ogee bracket toes have the ogee molding lower on the desk noticed. The ogee form is laid out on the tip of the inventory to function a information for adjusting the sawblade to the right depth of lower.

Then repeated cuts at numerous heights tough out the form. After slicing on the noticed comes the laborious activity of cleansing up the molding with carving gouges, gooseneck scrapers, and numerous grits of sandpaper (FWW #12). After cleanup, the molding is lower to the specified size, mitered, dadoed throughout the miter for the spline, assembled, and at last lower to form. For many residence craftsmen or small outlets, that is the best way to make steady ogee molding bases. However there may be one other methodology, based mostly on the bandsaw, for making ogee bracket toes as much as 6 in. or 7 in. lengthy. It’s sooner, and I feel easier, than the standard strategies.

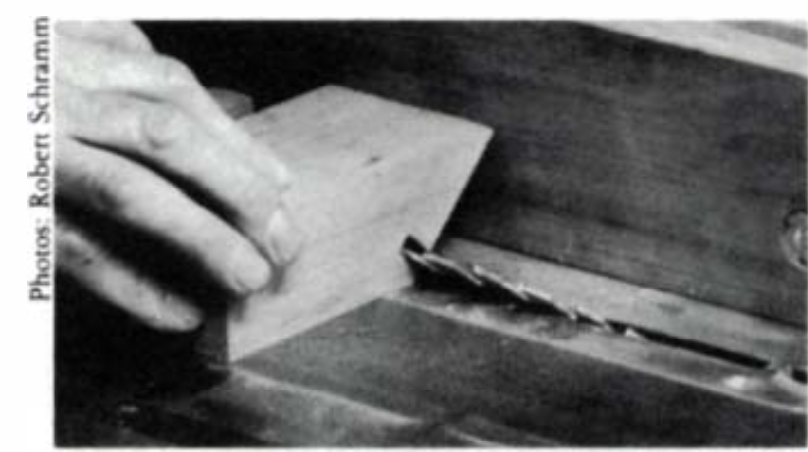

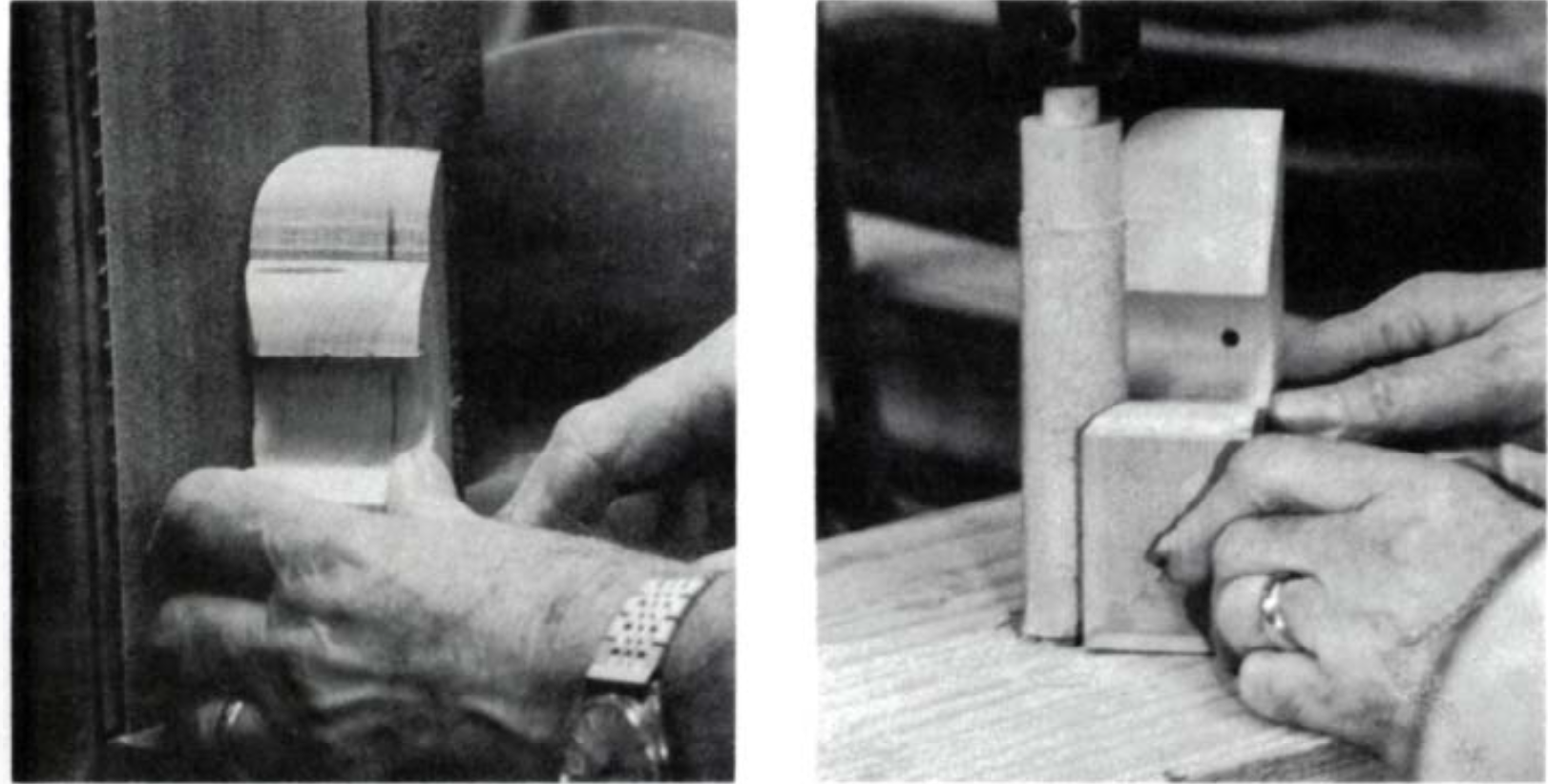

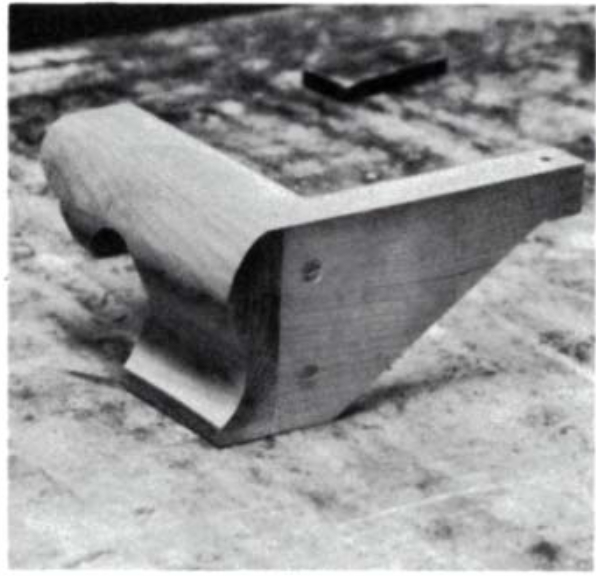

Start by slicing blocks 1-3/4 in. thick by 3 in. large by 6 in. lengthy, mitered at one finish. With the sawblade set at 45°, transfer the rip fence to the left of the blade and set the fence in order that the blade will lower a slot for the spline near the heel of the miter. Set the blade to chop 1/2 in. deep throughout the miter. After making the lower on all of the blocks, transfer the fence 1/8 in. farther to the left, increase the blade a fraction, and make the second lower to supply a 1/4-in.-wide dado. The spline could also be fabricated from 1/4-in. hardwood plywood with the face and again veneer grain operating lengthwise for optimum power, or from the identical materials used for the toes. The grain of a stable spline ought to cross the road of the miter, additionally for optimum power. Reduce the spline 1/4 in. thick by 3 in. large by 1 in. lengthy.

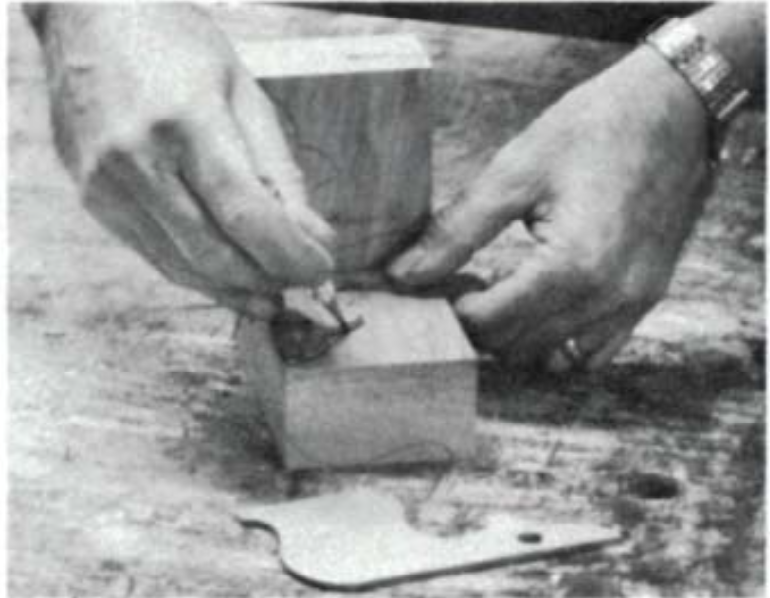

In preparation for assembling the blocks, I glue-size the tip grain first with a skinny coating of glue. This can preclude a starved joint by conserving the glue from being compelled into the pores of the wooden beneath clamping stress. After the glue measurement has dried, apply extra glue and assemble, positioning clamps to carry stress from each instructions.

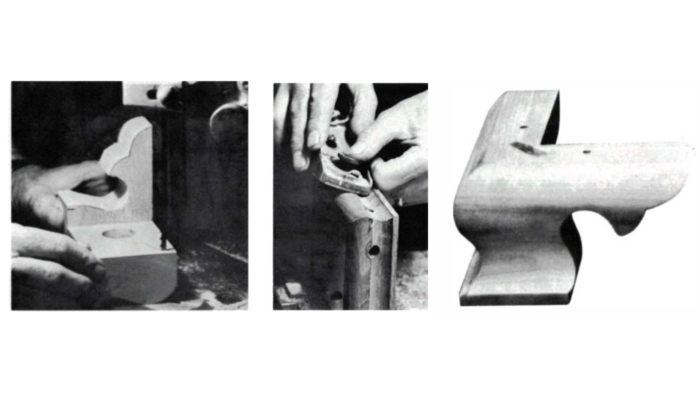

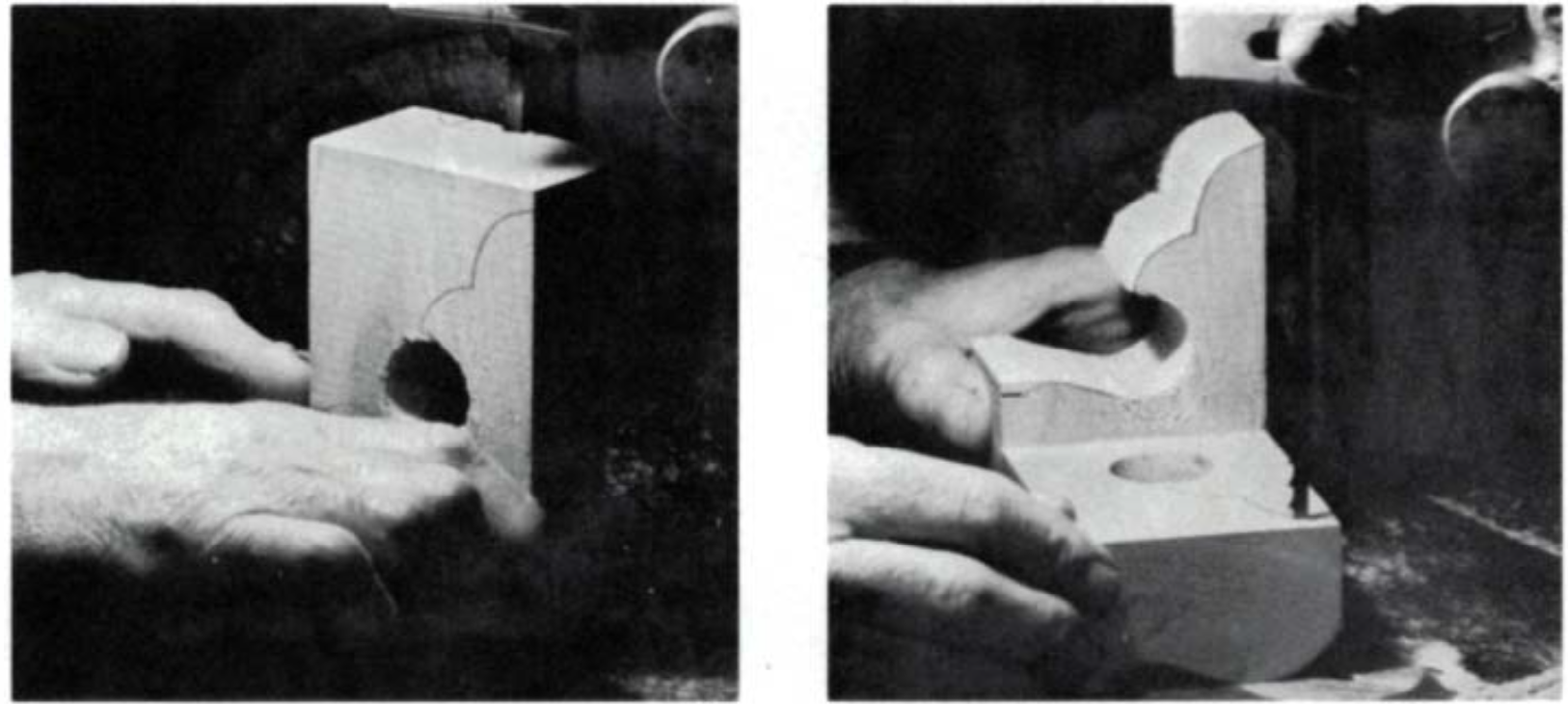

Utilizing templates made out of a sample, lay out the ogee form on the ends and inside faces of the assembled bracket.

Drill a 1-1/4-in. gap on the tightest a part of the curve. This must be performed earlier than slicing the ogee form to forestall any splintering on the face aspect of the foot. Then, to chop the ogee form, a pointy 1/4-in. or 3/8-in. bandsaw blade, correctly adjusted, will guarantee a straight lower with no drifting. Set the higher information about 1/4 in. above the work. Should you use a 3/8-in. blade, make one or two aid cuts within the concave a part of the ogee form to forestall the blade from binding. Reduce the second aspect of the bracket in the identical method. Now lower the outlined form.

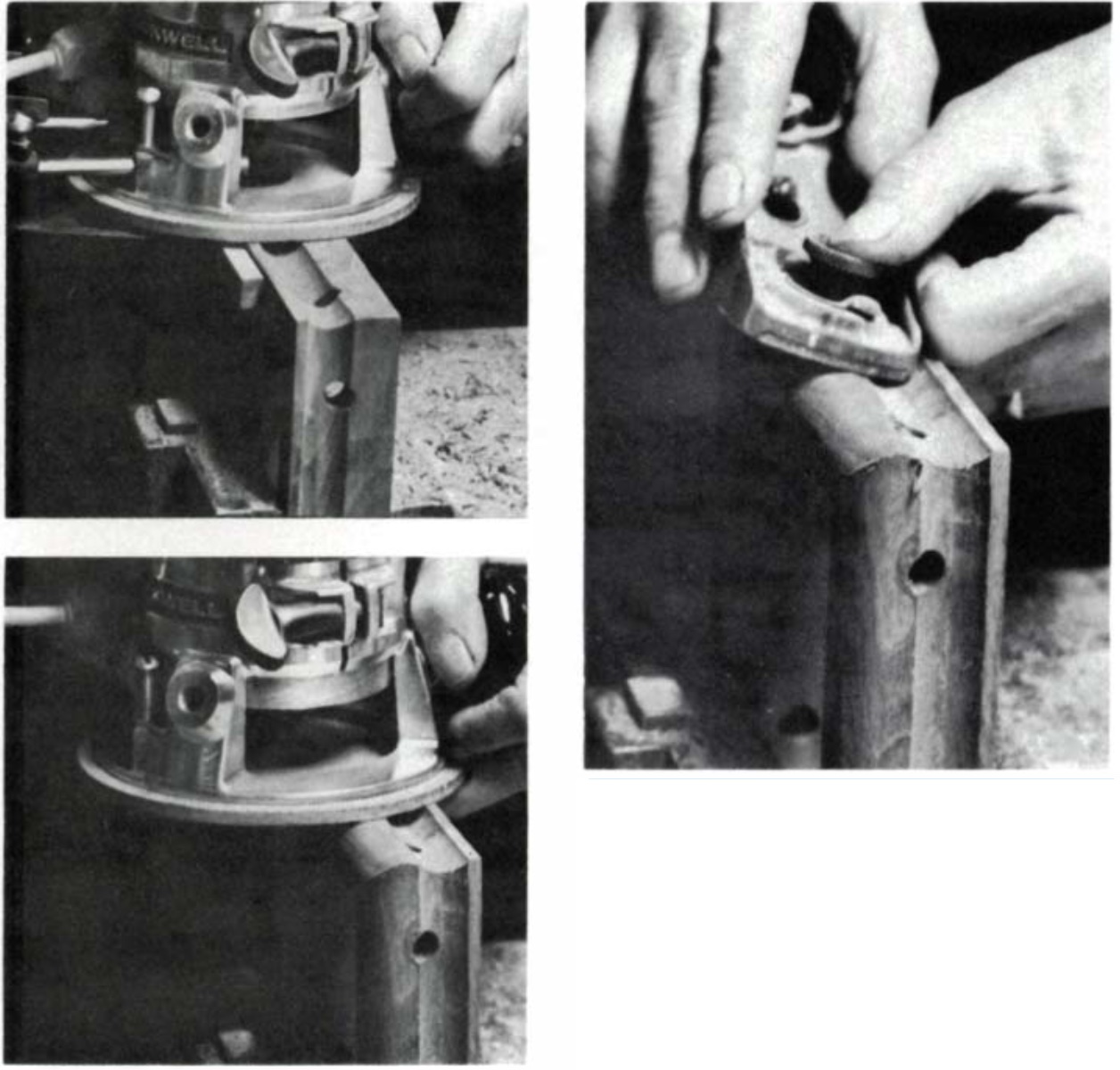

Sand the convex a part of the ogee on a belt or disc sander or by hand utilizing 60-grit sandpaper. The concavity could be sanded simply with a shop-made spindle on the drill press, or on the lathe. Remaining sanding is completed by hand with 100-grit sandpaper, adopted by 220. Drill 3/16-in. holes, countersunk for flat-head screws, to mount the finished foot.

After the body has been assembled, a router with a 3/4-in. core field bit cuts the concave a part of the ogee. Watch out to not lower too deep. Subsequent, rout the convex form with a 3/8-in. roundover bit. The ridge left by the core field bit could be eliminated with a block aircraft. The toes are then lower out on the bandsaw, sanded, and drilled for mounting.

Furnishings that may stand in opposition to a wall doesn’t require the ogee shaping on the again. In such circumstances, it’s essential to form solely the aspect of the foot. A plain picket brace, lower on the diagonal and hooked up with glue and screws, will present the required assist.

Join eletters immediately and get the newest strategies and how-to from Positive Woodworking, plus particular affords.

[ad_2]