[ad_1]

November 26, 2023 at 9:00 a.m.

By AEP Span.

In case you are used to working with metallic roofing and siding, then you already know oil canning is a prevalent situation.

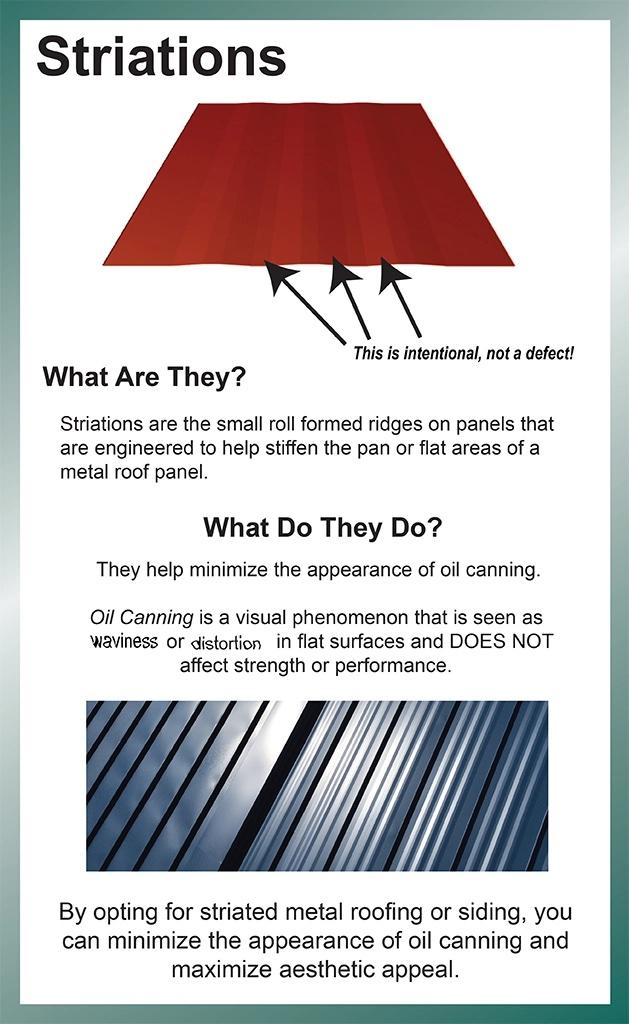

Oil canning is a phenomenon that refers back to the slight buckling or deformation present in sheet metallic, often seen on flat surfaces. It manifests as wavy or rippled traces that may have an effect on the general look of a constructing. Nonetheless, oil canning isn’t just an undesirable visible downside, it is a pure function of all cold-rolled flat metallic and so it mustn’t result in rejection. Many might discover the looks displeasing, however it’s necessary to acknowledge that it doesn’t compromise the metallic’s structural energy or its waterproofing capabilities. Let’s examine the underlying causes of oil canning and focus on potential treatments.

What’s oil canning?

Oil canning, also called stress wrinkling or elastic buckling, refers back to the seen waviness or rippling that may happen in metallic panels. It’s extra noticeable on flat or easy surfaces and might be fairly irritating for these searching for a seamless and blemish-free look.

Jeff Haddock, AEP Span Technical companies supervisor, mentions “Oil canning is attributable to inside stresses inside thin-gauge metals. These stresses might be launched through the manufacturing of the coil and fabrication of the panels. Subject set up methods, circumstances and building tolerances also can significantly influence the presence of oil canning.”

Seen rippling on the flat floor of the metallic siding panel

Frequent causes:

- Thermal Growth and Contraction: Steel expands and contracts with temperature modifications, and if the panel isn’t correctly put in or restrained, it will probably result in stress within the panel and end in oil canning.

- Manufacturing Imperfections: Variations within the manufacturing course of, similar to uneven stress within the metallic or variations within the thickness, can contribute to the problems.

- Improper Dealing with and Storage: Mishandling the metallic panels throughout transportation, storage or set up could cause distortion or dents, resulting in ugly appearances.

- Inadequate Substrate Assist: Insufficient structural assist and spacing between the framing members could cause the metallic panels to flex, resulting in a rippling impact.

Options to grease canning:

- Correct Set up: Following the producer’s tips for set up is essential to attenuate the chance of an ugly look. Correct fastening, spacing and assist are important to make sure the panels are put in accurately.

- Panel Choice: Selecting metallic panels with thicker gauges or selecting a panel with striations or ribs can assist scale back wavy or rippling appearances.

- Satisfactory Substrate Assist: Making certain the framing members are correctly spaced and structurally sound to assist decrease flexing.

- Common Upkeep: Conducting routine upkeep, similar to cleansing particles and inspecting for any indicators of injury, can assist forestall any points from worsening.

Keep in mind, oil canning might not all the time be utterly avoidable, particularly in sure climate circumstances or with intensive panel spans. Nonetheless, by understanding the causes and implementing applicable options, you’ll be able to considerably scale back the incidence and decrease the seen results of oil canning in your metallic roofing and siding mission.

For extra info, take a look at this nice article from Steel Building Information. For extra info on our metallic roofing and siding merchandise which might be designed to attenuate the looks of oil canning, take a look at our striated panel choices or contact our staff of specialists who can be comfortable to help you.

Unique supply: AEP Span

[ad_2]