[ad_1]

The information on this article sprang from a remark despatched in to Fantastic Woodworking’s Store Speak Stay podcast. “Yesterday I used to be reducing some shims on my bandsaw,” the listener wrote. “The piece I used to be reducing them from was fairly small, however I assumed to myself, ‘I can get one other one out of this.’ When my finger was about an inch from the blade, the shim and the offcut received dragged into the throat. There was a loud bang, and I jerked again. It damage so much. After a second to gather myself, I opened my fist to seek out my finger intact. The ache got here from the wooden exploding and hitting it. I fell asleep final night time thanking God for the wonderful blessing of my fingers.”

From handles and pulls to ft, wedges, wheels, drawer stops, and table-attachment tabs, woodworkers manufacture a good quantity of small components. Lots can go fallacious after we do.

Whereas these little components may be difficult to deal with with each hand instruments and energy instruments, hand instruments are normally safer, so at all times take into account these as an alternative choice to energy. That mentioned, it’s simpler to realize pace and precision with machines. And that’s the place small workpieces are their most harmful.

The excellent news is that the options are easy and simple. And, as is so usually the case in woodworking, protected methods additionally yield higher outcomes, so finest practices are a win-win.

The primary resolution: Shut the throat

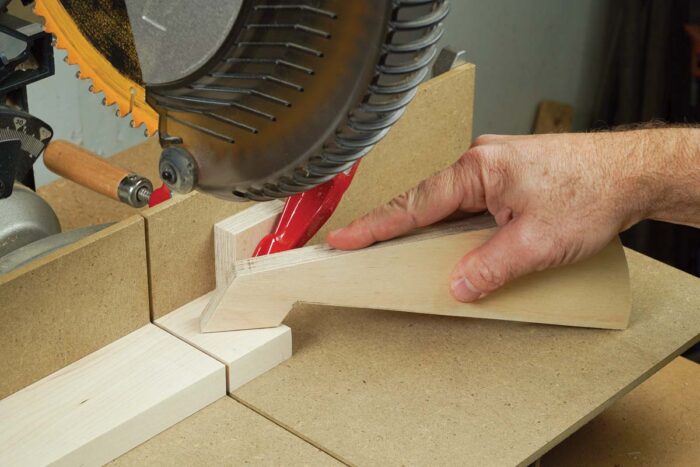

The primary pitfall in reducing small components is the one our podcast listener fell into—a gap across the blade that permits a small workpiece or offcut to be pulled into it, damaging it and probably pulling your fingers with it. Desk saws, miter saws, and bandsaws include giant blade slots that accommodate blades of assorted thicknesses, set at numerous angles. Many woodworkers discover a option to deal with this downside on their desk saws, realizing {that a} zero-clearance throat plate will forestall chipping on the underside fringe of all types of cuts. However we have a tendency to not deal with the difficulty on miter saws and bandsaws, partly as a result of zero-clearance is more durable to keep up on these machines, and since it isn’t at all times essential.

On all three machines, a panel or two of 1⁄4-in.-thick MDF is all you should create zero clearance across the bit or blade. These tight blade gaps won’t solely guarantee clear cuts and preserve small items from diving dangerously into a niche, however they will even present you precisely the place the blade will reduce, so you may align a format line with the slot, or hook a tape measure on it when establishing a cease.

-Desk noticed sled

|

|

Begin together with your table-saw sled. Set the blade to the miter angle you need, and use double-stick tape to connect a big piece of 1⁄4-in. MDF. Do the identical to the fence if wanted. Then reduce via the MDF (proper) to create zero-clearance help across the blade.

-Miter noticed

-Bandsaw

|

|

Zero clearance on the bandsaw. Minimize partway into a chunk of 1⁄4-in. MDF, then clamp it in place to create help across the blade.

Wait to show an extended piece right into a small one

The second resolution is likely one of the common ideas of protected, efficient woodworking. Think about the usual milling course of. The explanation we joint, aircraft, and rip components to thickness and width first—earlier than reducing them to size—is that longer items are safer and simpler to deal with on the jointer, planer, and desk noticed.

The identical goes for small workpieces. The thought right here is to do all the pieces you may to a small half (or components)—together with milling, shaping, drilling, and so on.—whereas it’s nonetheless half of a bigger piece. This can make a world of distinction relating to security and management, and it’s normally a extra environment friendly option to work.

You’ll be shocked in any respect the issues you are able to do to a small workpiece earlier than reducing it free from a bigger one.

|

|

Similar precept as the conventional milling course of. Milling brief components on a jointer or planer can vary from troublesome to unsafe. That’s why woodworkers mill components to thickness and width (above left) earlier than reducing them to size (above proper).

|

|

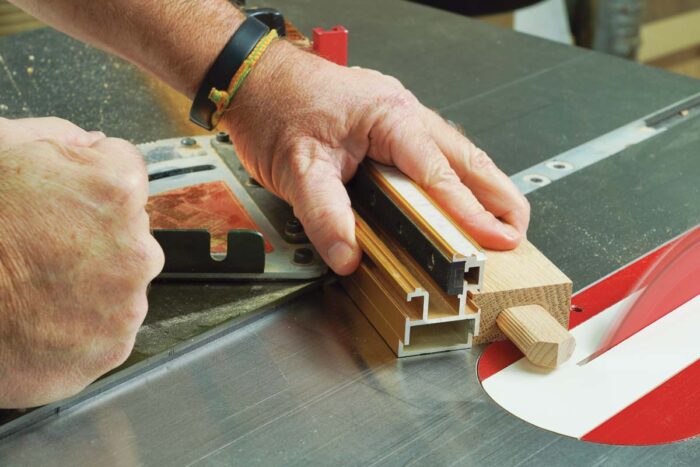

Lengthy components are safer than brief ones. In his Grasp Class on furnishings pulls (FWW #245), Ross Day reduce dadoes and slots in an extended workpiece, which turned a sequence of small posts (above left and proper).

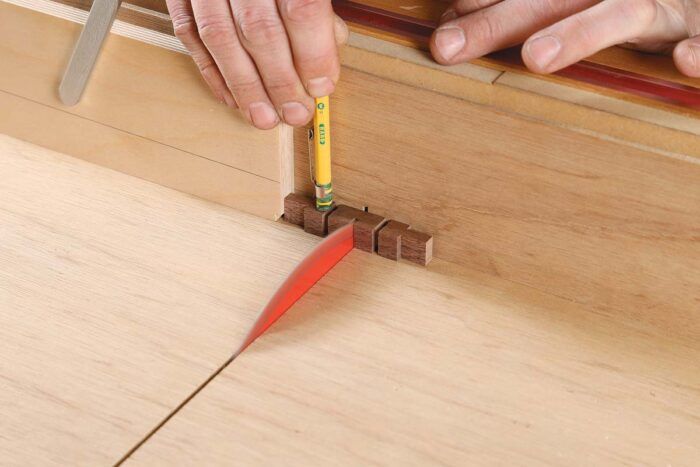

Add a provider. To chop 60° angles on the ends of Festool Domino tenons, so they might kind a threeway joint, FWW contributor Phil Gruppuso inserted the tenons in an extended scrap (under). Small workpieces will also be glued to bigger scraps for protected reducing or shaping, then reduce off afterward.

Reducing, shaping, and drilling small workpieces safely

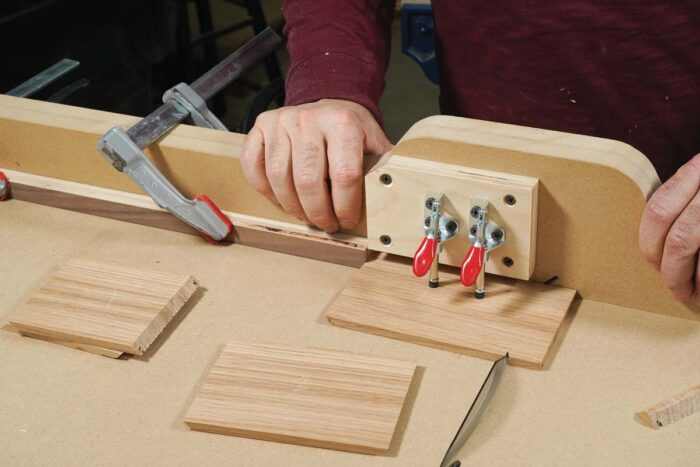

For very small workpieces, like little mitered moldings, small pins, miter keys, and so forth, my favourite cutoff software is a Japanese handsaw. However once I want much more precision, or a bunch of components reduce to the identical precise size, I flip to the desk noticed or miter noticed, including a cease of some type. It’s crucial to regulate the piece that’s trapped between the blade and the cease. There are a selection of efficient methods to regulate small cutoffs, as proven within the photographs.

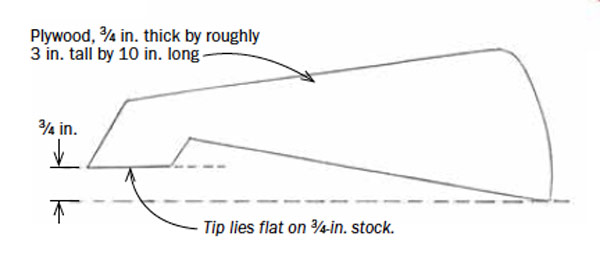

Pivoting Maintain-DownDo this helpful hold-down. This intelligent helper from FWW contributing editor Michael Fortune controls small components safely. In contrast to toggle clamps, it requires no setup. That is the final form of the hold-down. Christiana angles the tip to return down flat on 3⁄4-in. workpieces, however it’ll maintain down thicker and thinner inventory too. |

Though there’s numerous drilling and shaping you are able to do to small components earlier than reducing them off an extended piece, there can be occasions you’ll have to attend till the half is small and unwieldy. Generally it’s best to carry a small half in a bench vise, permitting you to work on it with a hand software or sanding block.

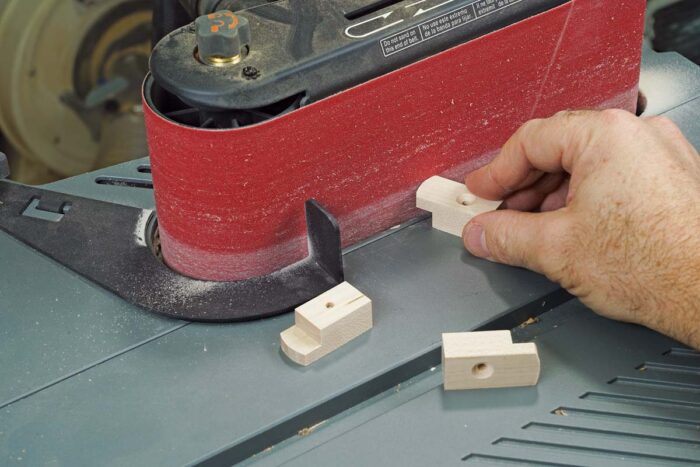

As a rule, nonetheless, to complete shaping small components, I flip to my benchtop sanding unit, which has a belt and a drum. It’s a very good choice for small components as a result of the almost definitely accident is a pores and skin abrasion, which is fairly simple to keep away from. When sanding small components on a disk, belt, or drum, preserve the piece on the desk in case you can. Use a agency grip and a lightweight contact.

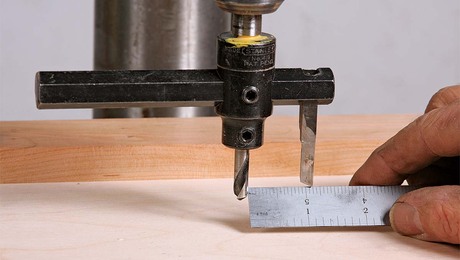

Drilling small components is much less harmful than shaping them usually. I normally do that on the drill press. All you’ll want usually is a fence and a cease, together with your fingers holding the half in place. But when the drill bit is giant, or the half desires to drag upward in a robust approach, I safe it within the jaws of a big hand-screw clamp.

There are many methods to work small components safely. These are a number of the best and finest I do know.

Asa Christiana is FWW’s editor-at-large.

Join eletters at present and get the most recent methods and how-to from Fantastic Woodworking, plus particular affords.

Obtain FREE PDF

while you enter your e mail deal with under.

[ad_2]